Le séchage en tour d’atomisation et la granulation par atomisation en lit fluidisé peuvent tous deux être utilisés pour convertir …

Les résultats confirment que le microniseur coaxial consomme en moyenne 23 % de gaz comprimé en moins que …

Seraplant et Glatt ont développé conjointement un processus de production hautement efficace, en attente de brevet …

Les secteurs de la chimie, de la chimie fine, de la pharmacie notamment ont besoin de pouvoir compter sur des …

Avec cette troisième extension depuis 2009, le site de Weimar est en passe d’assurer une nouvelle année de …

Le concept avancé PILOT mis au point par les ingénieurs de Schedio permet l’utilisation de différents modules de …

Doter son projet d’une phase de conception anticipée solide s’avère la meilleure approche pour rester en tête ...

ProCell Labsystem regroupe les technologies de lit venturi et lit fluidisé classique, pour l’agglomération, la …

L’agglomération par pulvérisation en lit fluidisé ouvre le champ à de nouvelles propositions de produits sous …

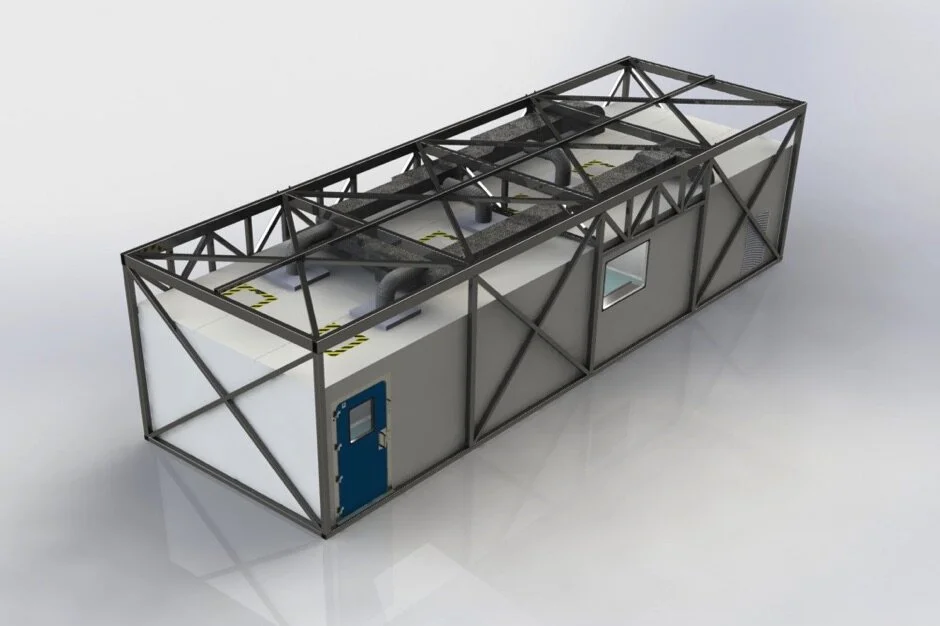

Les Laboratoires transportables MPL mis au point par le groupe ALBIAN reposent sur le concept de systèmes …

SCHEDIO combine la passion du développement de solutions innovantes et des applications de haute qualité .…

Les technologies à lit fluidisé et à jet venturi, Glatt permettent la conception et le montage des particules, parmi …

GLATT combine une expertise technologique et un réseau interdisciplinaire de tout premier plan. Grâce aux …

La Douche de Décontamination entièrement automatisée pour éviter le risque lié aux expositions de produits …